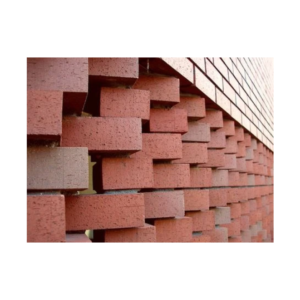

Description

Reliable Strength for Extreme Temperatures

At Dots Enterprises, we specialize in providing Castable Refractory Cement that meets the highest standards for strength, heat resistance, and durability. Perfect for various industrial applications, this cement is designed to endure the most demanding environments and ensures lasting performance where it counts.

Reliable Strength for Extreme Temperatures

- Unmatched Heat Resistance

Engineered for extreme temperatures, our refractory cement maintains stability, protecting structures from high-heat damage. - Excellent Durability

Resistant to thermal shocks, abrasion, and corrosion, ensuring that linings and surfaces remain intact over extended use. - High Versatility

Suitable for shaping and customizing for a range of industrial applications like kilns, furnaces, and boilers. - Easy Application

Simple to mix and apply, making installation more efficient and cost-effective for complex or large-scale projects.

Why Choose Dots Enterprises?

High-Quality Materials: Each batch of our refractory cement meets strict quality standards.

Expert Guidance: Our technical team offers support throughout the purchase and application process.

Prompt Delivery: Reliable logistics ensure timely delivery for uninterrupted operations.

Tailored Solutions: Customizable options are available for specific project requirements.

Applications of Castable Refractory Cement

Furnaces and Kilns: Provides effective insulation for industrial furnaces and kilns, improving energy efficiency and prolonging equipment lifespan.

Metal Casting: Withstands high thermal loads in metal foundries, supporting safe and stable casting processes.

Backyard Pizza Ovens: An excellent choice for home and commercial pizza ovens, ensuring even heat distribution and high insulation.

High-Temperature Boilers: Durable lining material for industrial boilers that minimizes heat loss and optimizes energy use.

How to Use Castable Refractory Cement

Surface Preparation: Make sure the application area is clean and dry.

Mixing: Follow specified water-to-cement ratios for optimal consistency.

Pour and Set: Pour into molds or directly onto surfaces, shaping as needed before it hardens.

Explore More at Dots Enterprises

In addition to Castable Refractory Cement, Dots Enterprises provides a variety of high-performance products, including Electric Heaters, Profile Cutting Machines, Glass Wool Insulation, and Hoist Chain Pulleys. Our solutions cater to both industrial and home project needs, ensuring premium quality and reliability.

FAQs – Castable Refractory Cement

What is Castable Refractory Cement used for?

Castable Refractory Cement is used to line high-temperature areas in industrial applications such as furnaces, kilns, boilers, and fireplaces. It provides heat resistance, thermal insulation, and durability under extreme heat conditions.

How do I apply Castable Refractory Cement?

To apply, mix the cement with water as per the recommended ratio, then pour or apply it to the desired surface. It can be shaped or molded into specific forms and should be allowed to cure properly before exposure to high temperatures.

How heat-resistant is Castable Refractory Cement?

Castable Refractory Cement is designed to withstand temperatures up to [Insert Temperature Range], making it ideal for applications that require high heat tolerance, including furnaces, kilns, and smelting equipment.

There are no reviews yet.