Description

Precision Cutting for Heavy-Duty Projects

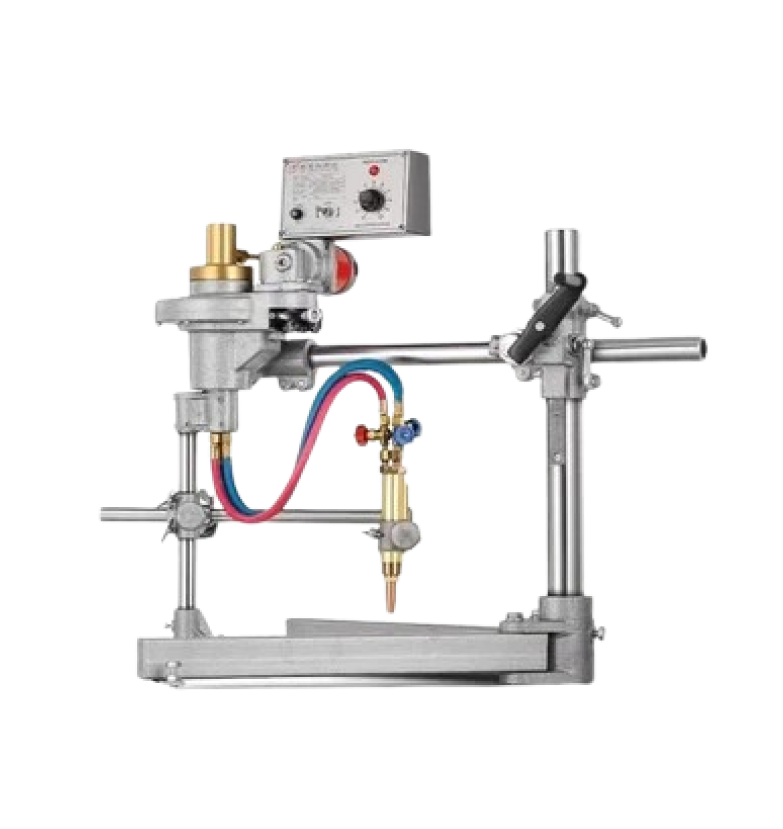

Dots Enterprises offers high-performance Flame Cutting Machines designed for precision cutting of thick materials like steel, metal, and other tough materials. Our cutting machines deliver superior efficiency, making them the ideal choice for industrial, manufacturing, and construction applications.

Benefits of Flame Cutting Machines

- Superior Cutting Precision

The flame cutting process allows for highly accurate cuts, even in thick metal plates, ensuring minimal waste and high-quality results. - Cost-Effective

With minimal material loss, flame cutting reduces costs and improves overall efficiency, particularly in large-scale projects. - High Efficiency

Flame cutting machines provide fast cutting speeds, reducing downtime and increasing production rates in high-demand environments. - Versatile Applications

Ideal for use in the construction, shipbuilding, automotive, and steel industries, as well as for custom fabrication needs.

Why Choose Flame Cutting Machines from Dots Enterprises?

Quality Assured: Our flame cutting machines are manufactured with high-grade components, ensuring long-lasting reliability.

Expert Assistance: Our team is available for technical support and operational guidance to help you get the most from your cutting equipment.

Flexible Solutions: We offer machines tailored to the specific needs of various industries, with options for different cutting sizes and speeds.

Reliable Delivery: We ensure timely delivery and setup assistance to get your equipment running without delays.

Explore More at Dots Enterprises

In addition to Flame Cutting Machines and Cutting Machines, Dots Enterprises offers a comprehensive range of industrial tools and machinery, including Castable Refractory Cement, Electric Heaters, Hoist Chain Pulleys, and more. We are committed to providing top-tier equipment for all your project needs.

Contact Us Today

Ready to enhance your cutting capabilities with high-quality machines? Get in touch with Dots Enterprises today to learn more about our flame cutting and general cutting machines, and request a quote!

FAQs – Flame Cutting Machine

What materials can the Flame Cutting Machine cut?

Our Flame Cutting Machines are ideal for cutting ferrous metals such as steel, iron, and other alloys. These machines are specifically designed to handle thicker materials, making them perfect for industrial applications where high precision and heat resistance are required. While flame cutting is most commonly used for metals, it is not suitable for non-metals like wood or plastics.

How do I maintain my Cutting Machine for optimal performance?

To ensure your Cutting Machine operates at peak efficiency, regular maintenance is essential. This includes:

- Cleaning: Keep the machine clean from dust, debris, and materials to prevent clogging or overheating.

- Lubrication: Apply the recommended lubricants to moving parts to reduce friction and wear.

- Inspection: Check the cutting mechanism and torch regularly for signs of damage or wear. Replace parts as needed.

- Calibration: Ensure the machine is properly calibrated to maintain cutting precision and accuracy.

Follow the manufacturer’s guidelines for specific maintenance instructions, and always perform routine checks to prevent downtime.

Can I use the Cutting Machine for both thick and thin materials?

Yes, our Cutting Machines are versatile and can be configured to handle a range of material thicknesses. Whether you’re cutting thin sheets of metal or thicker plates, the machine can be adjusted to accommodate various cutting methods such as laser, plasma, or water jet. The machine’s cutting speed, pressure, and temperature settings can be tailored for optimal performance depending on the material and thickness.

There are no reviews yet.